District cooling systems are increasingly being adopted in cities and industry as an economical and environmentally friendly way of managing bulk air conditioning loads. The systems supply chilled water or other cooling media in insulated pipe networks to several buildings, saving energy and lowering operations complexity compared to building-level chillers. As such systems evolve to provide more efficiency and environmental performance, the addition of microchannel heat exchangers is becoming a strategic enhancement—particularly in terms of maximizing thermal transfer, reducing maintenance, and increasing system life.

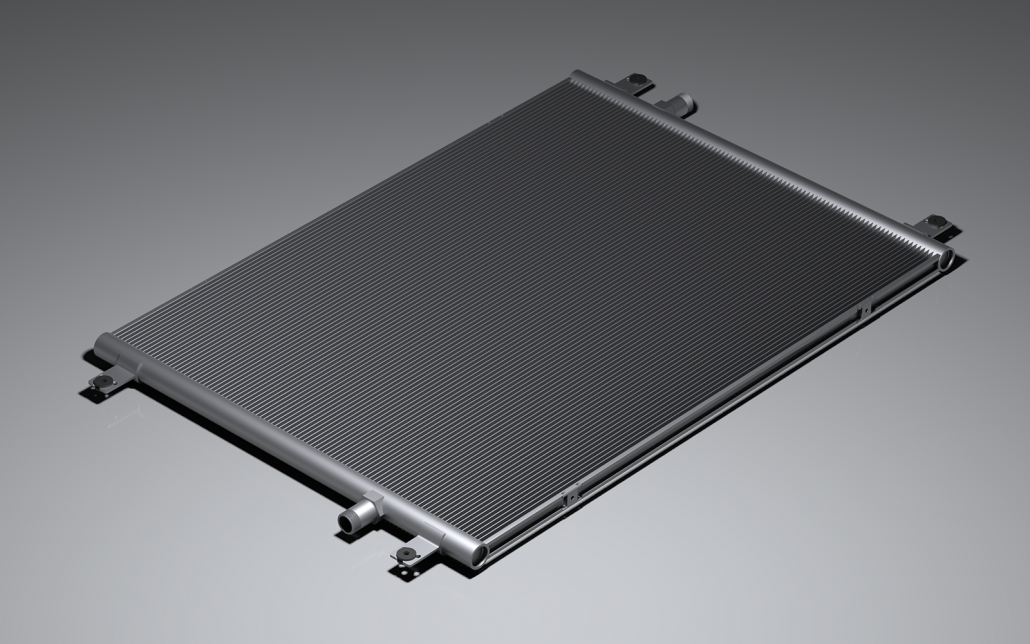

The fluid coil is one of the key components in any district cooling setup, allowing for the transfer of thermal energy from the chilled distribution loop to the indoor air handling units. Traditional fluid coil configurations normally make use of copper tubing with aluminum fins, but these are prone to corrosion by moisture, chemical impurities, or fluctuating fluid temperatures. Microchannel heat exchangers offer a promising solution using flat aluminum tubes with internal multiple channels, which enhance performance and integrity without contributing to system complexity.

Higher Thermal Efficiency and Reduced Energy Consumption

One of the main advantages of microchannel technology for district cooling is its ability to achieve greater heat transfer rates at lower pressure drops. The multi-channel design increases contact between the cooling fluid and coil walls, resulting in more uniform heat distribution and shorter response time. This results in more efficient operation, allowing chillers to run at lower capacities without compromising cooling demands across large buildings or even entire city blocks.

In addition, because microchannel coils require less charge of chilled water or refrigerant to perform similarly, they support more responsive control schemes. In district cooling systems where load variability is common, this translates to tighter temperature regulation, reduced compressor cycling, and overall lower energy usage—a significant consideration for operators interested in maintaining utility costs and carbon footprints as minimal as possible.

Durability and Low Maintenance in Harsh Environments

District cooling systems run continuously year-round, and therefore reliability is of the utmost concern. Formicary corrosion may be experienced with conventional fluid coil designs due to exposure to volatile organic compounds (VOCs) found in most indoor spaces. This will result in leaks, inefficiencies, and replacements over time.

Microchannel heat exchangers, constructed primarily of aluminum, are more resistant to such degradation. Hydrophilic coatings promoting drainage of condensate and inhibiting microbial growth are included in most models—especially beneficial in high-humidity applications, where moisture can accelerate material degradation. Microchannel designs feature fewer seams and joints than standard coils, and with fewer potential leak points, there is less risk of unplanned downtime, still longer service life.

For those who build new district cooling plants or retrofit existing ones, the adoption of fluid coil components manufactured with microchannel technology offers long-term benefits both in performance and maintenance. Deployed in central plant chillers, heat recovery systems, or air handlers on a building level, such advanced coils are a resilient, cost-effective answer to the unique demands of thermal distribution on a large scale.

Conclusion: A Smart Investment for Sustainable Urban Cooling

As the cities continue to expand and efficient, eco-friendly cooling is in greater demand, district cooling systems are becoming a significant part of infrastructure planning today. By incorporating microchannel heat exchangers—particularly in vital aspects like the fluid coil —the systems can achieve higher levels of efficiency, strength, and sustainability.

From more effective thermal transfer and lower energy costs to extended service life cycles and greater corrosion resistance, the advantages of microchannel technology are clear. For facility managers, urban planners, and HVAC engineers, adopting this innovative technique for heat transfer isn’t just a question of keeping current with the latest developments—it’s a question of creating smarter, more sustainable cooling networks for tomorrow.